Gazpacho

Transform Data into Action, Waste into Value.

Ready to turn your data into action and waste into value?

Book a 30-minute meeting with Gazpacho today!

Drop your information below, and we’ll get in touch to arrange a demo, provide a personalized quote, or discuss solutions crafted specifically for your needs.

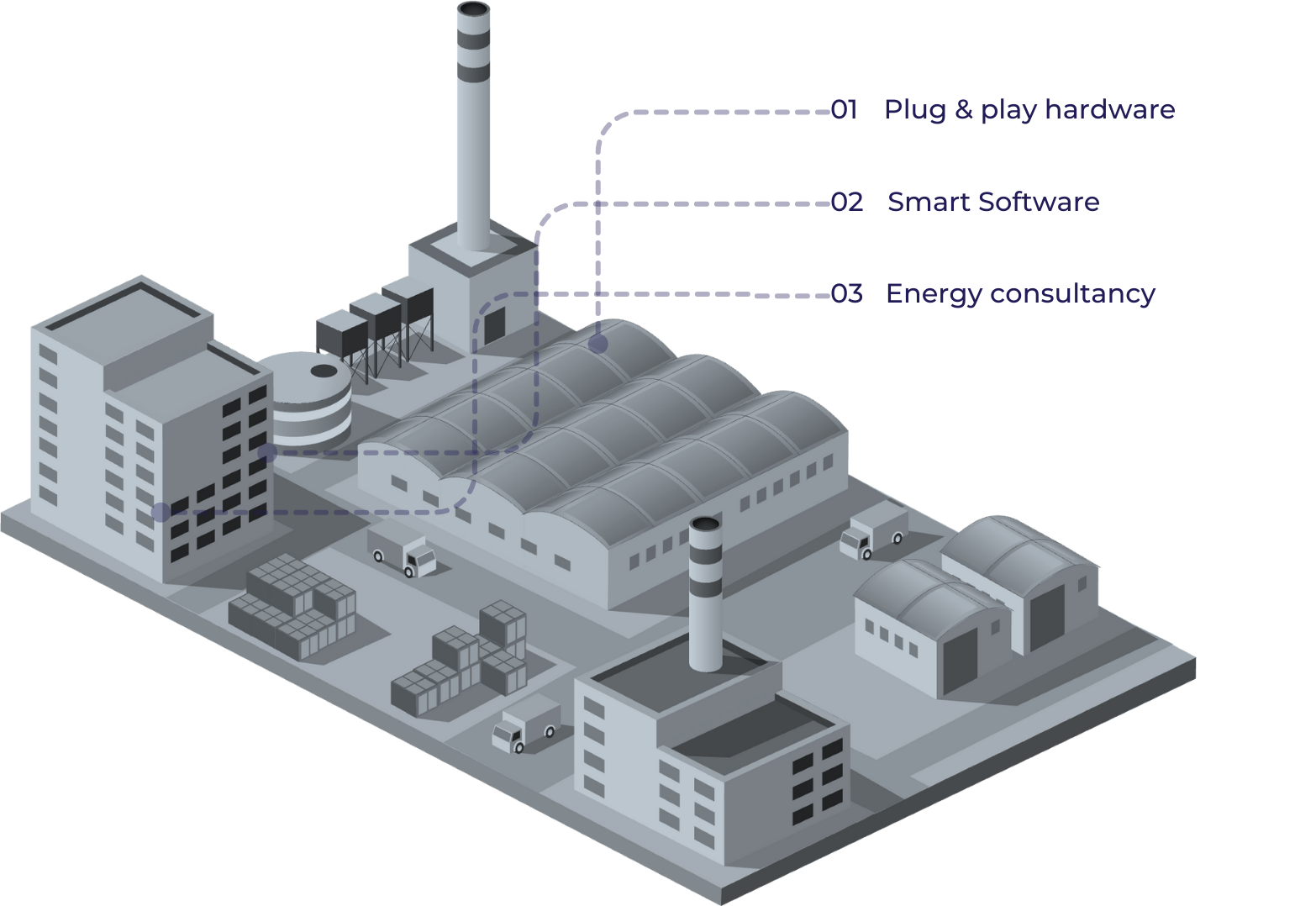

3 Unique features

Gazpacho Analytics

Manufacturers often accept inefficiencies due to a lack of visibility into asset utilization.

“Gazpacho Assets Analytics”

provides operators with valuable insights into asset performance, usage patterns, and movement history. By leveraging data-driven analytics, businesses can optimize asset allocation, reduce waste, and improve overall operational efficiency.

Gazpacho Asset Tracking

Delays in material flow and misplaced equipment can lead to production slowdowns increased costs & frustrated customers.

“Gazpacho Real-time Tracking”

ensures that operators always know where their critical assets are at any given moment. With continuous monitoring, businesses can streamline workflows, minimize downtime, and enhance overall productivity by keeping operations running smoothly.

Gazpacho Energy

Energy price fluctuations in a volatile world present a substantial challenge for manufacturers.

“Gazpacho Energy”

allows operators to understand where and when energy is being used. The granular analysis allows energy to be optimised at a machine or workstation level.

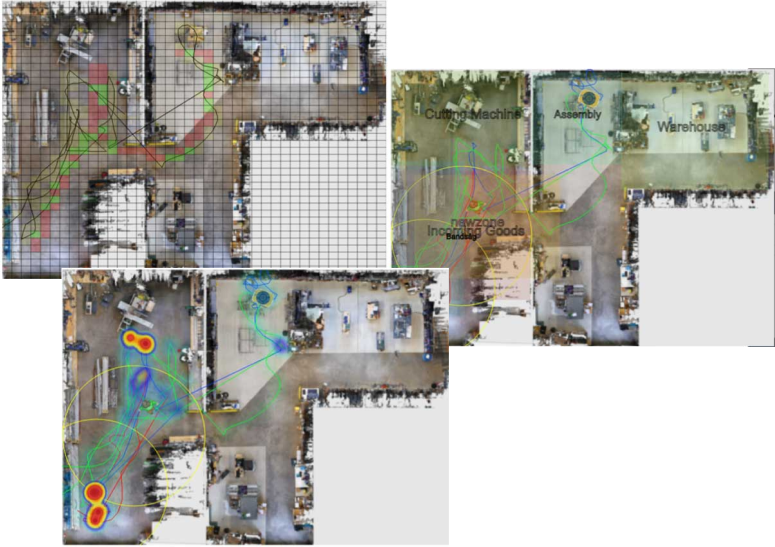

Gazpacho Analytics

- Spaghetti and heatmap visualization

- Geofencing

is used to track movement and time spent in specific areas to improve efficiency. It helps identify inefficiencies by monitoring how long processes take in designated zones.

- Customer defined KPI’s

- Define standard paths:

by manually drawing spaghetti diagrams and comparing them with actual data. This provides a clear picture of movement and work patterns, highlights deviations from standard paths, and identifies bottlenecks in the process.

- Find risk of collisions

- Compare datasets

- Time, method and sequence integration:

Tracks key metrics such as moving vs. standing still time, work area efficiency, acceleration, deceleration, and collision risks using advanced data models.

- Customer driven development

Analytics Improvement

AS IS

- To complete a SMED process, 5 people need to monitor the machine setup for 1 hour.

- An additional 5 people are required, each working for 1.5 hours.

- Total time spent on the SMED spaghetti diagram: 7.5 hours.

TO BE

- The same 5 people monitor the machine setup for 1 hour but now utilize Gazpacho Analytics spaghetti tracking for efficiency.

- Setup time per person is reduced to 0.5 hours, resulting in a total of 2.5 hours instead of 7.5 hours.

- Total time saved: 5 hours (67% reduction).

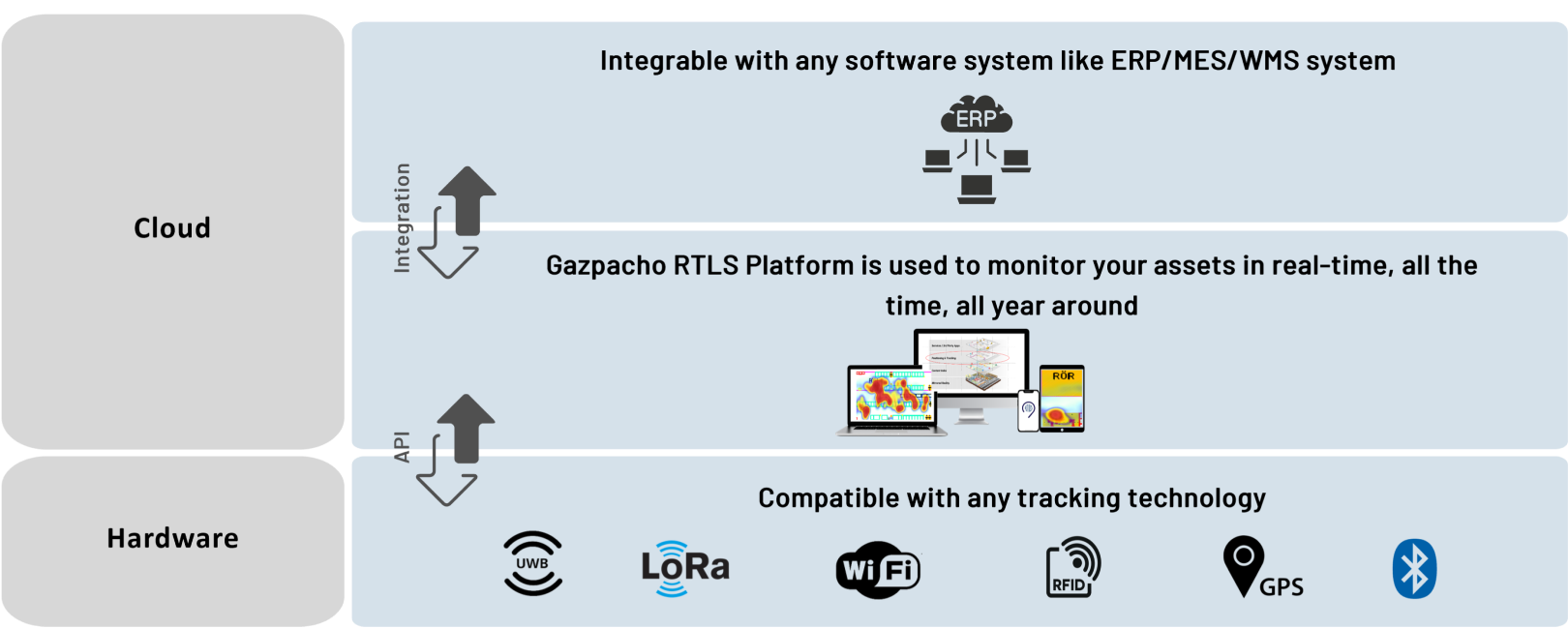

Gazpacho Asset Tracking

- Real-time visibility & tracking

- Automated spaghetti diagram

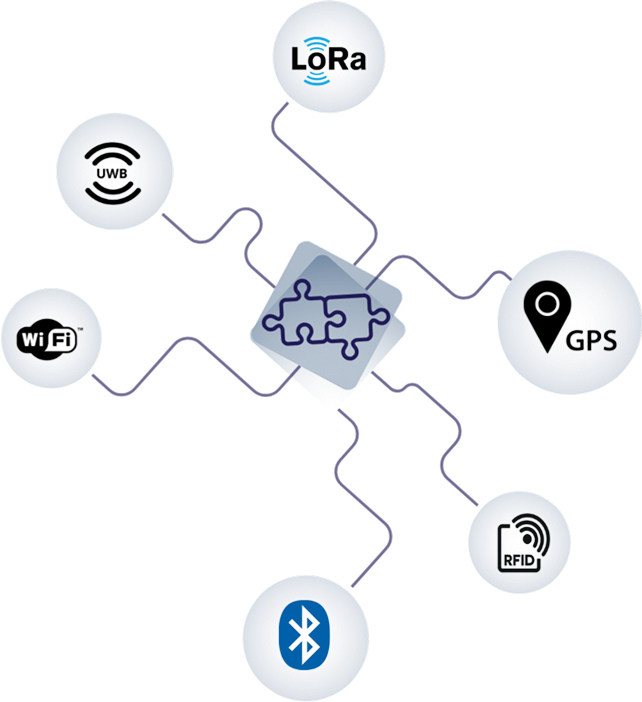

- Compatible with any tracking technology

- Seamless integration with ERP, MES, WMS, and other systems

Gazpacho Energy

- Machine/Workstation energy tracking

- Utility tracking, Air, Water and Electricity

- Utility consumption analysis

- Usage patterns identification

- Detection of inefficiencies

- Strategic recommendations for optimization

- Data as the basis for improvement activity allows the results to be assessed

Energy Improvement

02 Smart Software

03 Energy consultancy

01 Plug & play hardware

Gazpacho as a software platform

- Energy consumption analysis

- Patterns

- Inefficiencies

- Suggest strategies to reduce inefficiencies

- Current monitoring sensors

- Pulse counters

- Temperature monitoring

- Occupancy monitoring

01 Plug & play hardware

- Current monitoring sensors

- Pulse counters

- Temperature monitoring

- Occupancy monitoring

02 Smart Software

Gazpacho as a software platform

03 Energy consultancy

- Energy consumption analysis

- Patterns

- Inefficiencies

- Suggest strategies to reduce inefficiencies

Global Manufacturer Deploys at 4 Locations

Global Manufacturing Expansion

A global manufacturer deploys at 4 manufacturing locations with plans for an additional 4 locations

Andon for Mobile Workers

Andon functionality added for workers not located at dedicated workstations

Tracking WIP and Non-WIP Production Assets

Initial use case was based on gaining "Visibility" of WIP and non-WIP production assets (eg FLT's, special tooling, test equipment etc.)

Big Data Analytics for Operational Efficiency

Customer and VM now working on "Big data analytics" based on ERP and location data to support Net Working Capital improvement, Factory Floor utilisation, Lead Time reduction etc.

Exceeds Payback Expectations

Payback exceeded expectation on initial use case

Immediate Returns with Long-Term Potential

Short term gains have paid for the implementation but 10x benefits expected from use of data

Integrations

AWS

Azure

Google Cloud

SAP

MS Dynamics

ERP

APS

WMS

Composable

MES/TULIP

- AWS

- Azure

- Google Cloud

- SAP

- MS Dynamics

- ERP

- APS

- WMS

- MES/TULIP

Composable

Trusted partners

Pricing

Gazpacho Analytics Feature

“Powerful Analysis Tools – Unlock Efficiency, Avoid Risks”

- Spaghetti and heatmap visualization

- Geofencing

- Customer-defined KPIs

- Define work areas

- Define standard paths

- Risk of collisions detection

- Compare datasets

- Time, method, and sequence integration

- Customer-driven development

Interested in Gazpacho Analytics Feature

Ready to turn movement data into actionable insights?

Book a 30-minute meeting with Gazpacho today!

Drop your information below, and we’ll get in touch to arrange a demo, provide a personalized quote, or discuss solutions crafted specifically for your needs.

Gazpacho Energy Feature

“Optimize Energy and Production Processes with Gazpacho Energy – Effective Solutions for Cost Reduction and Sustainability”

- Multi-device energy tracking per shift

- Energy consumption analysis

- Utility tracking, Air, Water, and Electricity

- Utility consumption analysis

- Usage patterns identification

- Detection of inefficiencies

- Strategic recommendations for optimization

Interested in Gazpacho Energy Feature

Ready to optimize energy usage and turn waste into savings?

Book a 30-minute meeting with Gazpacho today!

Drop your information below, and we’ll get in touch to arrange a demo, provide a personalized quote, or discuss solutions crafted specifically for your needs.

Gazpacho Asset Tracking RTLS Feature

“User-Friendly Web and Cloud- Based Tracking Software”

- Real-time visibility & tracking

- Automated spaghetti diagram

- Compatible with any tracking technology

- Seamless integration with ERP, MES, WMS, and other systems

Interested in Gazpacho Asset Tracking RTLS Feature

Ready to track assets in real time and enhance operational flow?

Book a 30-minute meeting with Gazpacho today!

Drop your information below, and we’ll get in touch to arrange a demo, provide a personalized quote, or discuss solutions crafted specifically for your needs.

Ready to turn your data into action and waste into value?

Book a 30-minute meeting with Gazpacho today!

Drop your information below, and we’ll get in touch to arrange a demo, provide a personalized quote, or discuss solutions crafted specifically for your needs.

See Gazpacho Transform the Way You Work!

Gazpacho is a suite of digital solutions developed by Virtual Manufacturing, a company specializing in lean-based production and logistics optimization. Learn more about our company and other solutions on Virtual Manufacturing’s official website.

VIRTUAL Manufacturing Sweden AB, HQ

Fabriksgatan 21

412 50 Göteborg

Sverige

+46 31-26 55 44

VIRTUAL Manufacturing Region East & Central

Molijns Väg 21

589 41 Linköping

Sweden

+46 31-26 55 44

VIRTUAL Manufacturing UK Ltd

The Bield

Hartree Entries Road

Bigger, Scotland

ML 12 6IT

+44 7368 950 111

VIRTUAL Manufacturing Thailand Co. Ltd

630 On-nuj 54, On-nuj,

Sukhumvit 77 Road,

Suanluang

10250 Bangkok

+66 63 464 0724

VIRTUAL Manufacturing China, C/O Youxin Parts Co. Ltd

Room 3119 – Yinzhou Chamber of Commerce North Building- No. 1299 Yinxian Avenue 315105 Ningbo Zhejiang